Okay, so Ford’s back in the engine-making game in Chennai, specifically for exports. You might be thinking, “Okay, cool. Good for them.” But here’s the thing: this isn’t just about some factory churning out parts. This move has implications that ripple through the Indian automotive sector and beyond. Let’s dive into the “Why” angle, shall we? Why is Ford , specifically Ford engine production , restarting in India a big deal, even after they officially left the Indian market?

The Strategic Shift | More Than Just a Comeback

Ford’s exit from Indian domestic manufacturing in 2021 was a pretty big blow, let’s be honest. It left a void, and a lot of people wondered if other international players would follow suit. But this resumption, focusing solely on exports, signals something very different. It’s not a retreat; it’s a recalibration. They’re leveraging India’s manufacturing capabilities – its skilled workforce, relatively lower production costs, and established supply chains – to serve global markets. It’s like they realized, “Wait, we can still use this amazing infrastructure, just not for here.”

The automotive industry is a global game, and India’s becoming an increasingly important piece of that puzzle. Think about it: we’re strategically located, and we have a government that’s pushing for manufacturing growth through initiatives like “Make in India.” Ford’s move is a vote of confidence in India’s potential as a global export hub for automotive components.

Chennai’s Engine Hub | Why Here, Why Now?

Chennai, often dubbed the “Detroit of India,” is no stranger to automotive manufacturing. It already boasts a robust ecosystem of suppliers, skilled labor, and logistical infrastructure. Chennai’s auto industry is well known. Ford’s decision to restart operations here isn’t random. They’re tapping into existing strengths. Plus, they likely have long-term contracts and established relationships with local suppliers, making it easier and more cost-effective to resume production.

And, let’s be real, restarting an engine plant isn’t like flipping a switch. It requires significant investment, re-training of personnel, and re-establishment of supply chains. The fact that Ford is willing to do this indicates that they see long-term profitability in exporting engines from India. This isn’t a short-term gamble; it’s a strategic play.

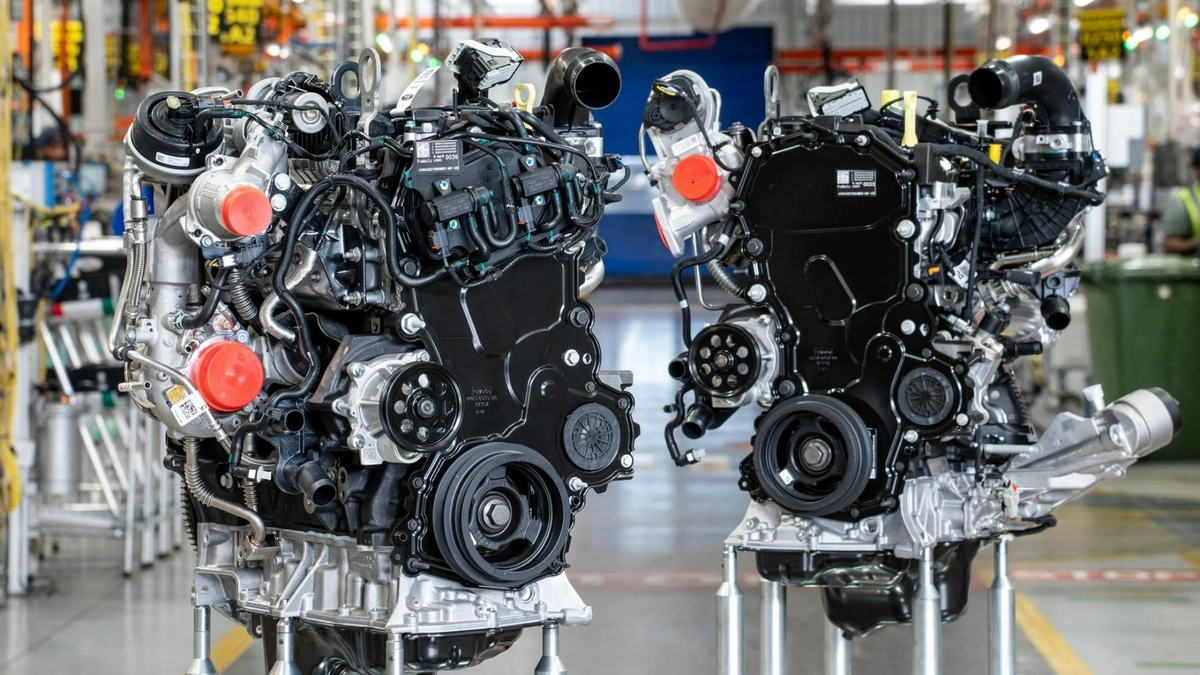

What Engines Are We Talking About? And Where Are They Going?

Ford hasn’t explicitly stated which engines they’ll be manufacturing in Chennai, but industry analysts speculate that it will likely be engines for their global truck and SUV lines. Why? Because those are high-demand, high-margin products. And exporting engines for those vehicles from India could significantly reduce production costs. The company , is likely to be focusing on modern, fuel-efficient engines that meet global emissions standards. This is crucial because export markets, particularly in Europe and North America, have strict regulations.

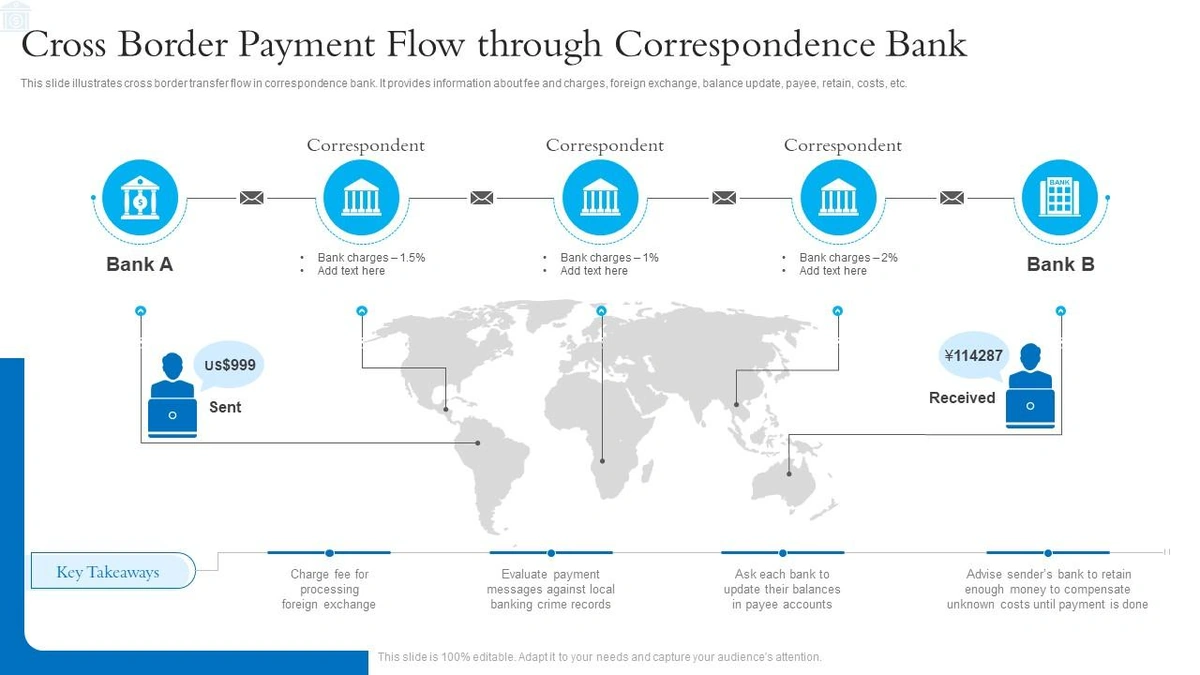

The destination of these engines is also key. Are they going to Ford’s assembly plants in Europe, South America, or elsewhere in Asia? This will give us a clearer picture of Ford’s global manufacturing strategy. It’s all interconnected, you see. The global supply chain for the auto industry is a complex web, and Ford’s Chennai plant is now a node in that web.

The Ripple Effect | Jobs, Investment, and India’s Reputation

Beyond Ford’s bottom line, this move has broader implications for India. It means job creation, both directly at the plant and indirectly through the supply chain. It also attracts further investment in the automotive sector. When one big player like Ford shows confidence in India, it encourages others to take a closer look.

But perhaps most importantly, it enhances India’s reputation as a reliable and competitive manufacturing hub. This is crucial for attracting more foreign investment and boosting India’s overall economic growth. It’s a virtuous cycle, really. More investment leads to more jobs, which leads to more economic growth, which leads to… well, you get the idea.

The decision related to Chennai manufacturing plant shows the importance of India in the global auto industry. Now, what about those automotive components? Ford may be able to leverage the ‘Make in India’ policy to boost the economy.

Challenges and Opportunities Ahead

Of course, it’s not all sunshine and roses. Ford will face challenges, including navigating complex export regulations, managing supply chain disruptions, and maintaining quality control. And, let’s not forget, they need to compete with other engine manufacturers in the global market. Overcoming these hurdles will require careful planning, efficient execution, and a relentless focus on innovation. The competition is tough.

But the opportunities are immense. If Ford can successfully leverage its Chennai plant to produce high-quality engines at competitive prices, it can significantly boost its global competitiveness and contribute to India’s economic growth. It’s a win-win situation, potentially.

Consider engine export figures in the coming months. Any change would indicate positive or negative trends.

Ford’s Second Act in India

Ford’s decision to resume engine manufacturing in Chennai for export is more than just a business decision; it’s a strategic move that reflects the evolving dynamics of the global automotive industry. It’s a testament to India’s growing importance as a manufacturing hub and a vote of confidence in its long-term potential. But it also has a message for all automotive industry experts.

It’s a complex story, with many moving parts. But one thing is clear: Ford’s second act in India is just beginning, and it has the potential to be a major success story. We’ll be watching closely to see how it unfolds.

FAQ Section

What kind of impact would this have on the Indian economy?

This move will create jobs, attract investments, and enhance India’s reputation as a manufacturing hub.

What are the challenges that Ford might face?

Ford needs to navigate export regulations, manage supply chains, and maintain quality.

Where will these engines be exported?

Likely to Ford’s assembly plants in Europe, South America, or Asia.

What kind of engines will be manufactured?

Likely engines for Ford’s global truck and SUV lines.